Alshibli’s Quest Takes Him to the Particle Level

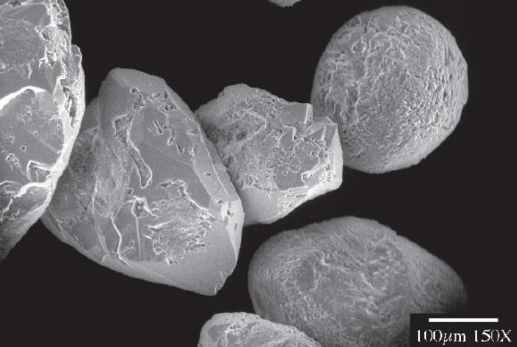

Magnified Ottowa sand grains.

Highlights

- There is not yet an underlying model of the behavior of sand at the particle level that can be applied across all applications.

- UT Professor Khalid Alshibli is using computer simulations to develop a fundamental theory to understand this behavior.

- Such a theory would benefit a wide range of industry applications.

Anyone who’s walked barefoot on the beach knows the feeling of sand compressing and shifting under their feet. In a basic sense, this behavior of sand is what piqued the interest of Professor Khalid Alshibli.

As a geotechnical engineer, Alshibli knows his colleagues are focused mainly on granular materials, work that typically involves collecting samples and performing experiments. With sand, however, there is no underlying theory offering the best solution.

Alshibli and his research team are hoping to change that.

For six years, his research has focused on developing tests to observe, measure, and image the properties of silica grains when different loads are applied to them.

By taking images of silica sand at a size of 0.2mm, the team aims to establish a fundamental theory that will provide a better understanding of the behavior of sand at the macro scale for use across industries, including agriculture and pharmaceuticals.

Sand is composed of discrete particles that vary in shape and interact with each other in a complex fashion. Silica, in particular, has the characteristic of being anisotropic—it’s different when measured along different axes.

Because of particle morphology, orientation, and contact configuration, it’s been historically difficult to identify the properties of granular materials. At the particle level, the crystalline structures within the grains change when stress is applied, so the team is working on gathering many thousands of images and measurements of the load stress impacts for the research.

—Khalid Alshibli

He added, “I’d like to thank the National Science Foundation (NSF) for funding our research and the Advanced Photon Source (APS) that enabled us to acquire unique measurements at world-class facilities.”

Of course, any theoretical model needs to be validated. Three times per year, the team visits APS in Chicago to use the facility’s CT and X-ray diffraction beamline, which provide them images similar to CAT scans used in the medical field.

With the data they’ve collected, the team is developing a framework for Finite Element Modeling that can provide computer simulations that predict the behavior of sand under different conditions.

Having successfully measured the influence of how the anisotropy of individual sand grains affects the way they carry and transmit loads, the team has now developed a computational code to analyze and measure the particles, their physical properties, and their behavior.

Obtaining accurate three-dimensional characterization has been especially difficult for minute particles like silica grains, but developments in 3D imaging and coding technology have advanced, enhancing the team’s capabilities.

Alshibli’s team uses natural silica sand from Illinois—the same sand used in many industrial applications—as well as synthetic silica cubes that have a single crystal structure and simple geometrical shape.

Using both forms of silica allows the team to see how stresses develop with different shapes and particle-to-particle interaction, down to the crystalline level.

So, when you next take a long walk on a beach, think about all the many grains of sand interacting with each other as you walk and remember that this is a cutting-edge area within geotechnical engineering.

Contact

Élan Young: elan@tennessee.edu