Your dental floss, your sofa, and your iPhone have something in common—or, more accurately, thousands of somethings.

And they’re all bad for your health.

Per- and polyfluoroalkyl substances, known as PFAS, are synthetic molecules first introduced in the 1940s. PFAS have water and grease-repelling properties that are necessary in some industries, but make them dangerous conveniences elsewhere.

“When you spill soda on your couch and it beads up, that’s because of PFAS,” said Professor Frank Loeffler. “If your dental floss slides very nicely between your teeth, it’s because of PFAS. They also create a very stable foam—in fact, the best firefighting foam we know of is made of PFAS. These things are everywhere.”

The production of PFAS has created mixtures of thousands of different molecules, which makes tracking their progress through the environment and assessing their health impacts extremely challenging. Nonetheless, several PFAS have been linked to the development of cancer, diabetes, and obesity. Some can compromise the immune response, making vaccines less effective.

Unfortunately, their prevalence makes them unavoidable.

“PFAS are pervasive,” said Cindy Swift, a research associate in the Loeffler lab. “I could take a sample of anyone’s blood right now and I would find PFAS.”

For decades, PFAS have been considered recalcitrant (difficult to degrade), which has earned them the title of “Forever Chemicals.” However, recent research is challenging this paradigm.

The Loeffler lab has found naturally occurring bacteria that can digest fluorinated compounds, including certain PFAS, suggesting that nature has evolved mechanisms of destroying them. Demonstrating that PFAS will not persist “forever” would be a major achievement, as it could lead to mitigation strategies and management approaches that protect human health and the environment.

Without policy changes and the development of alternatives, the flow of PFAS into the environment—and our bodies—will continue. PFAS are still produced and used in many industries all over the world. They are simply too useful to eliminate.

“Until we have some alternative, the military and firefighters still need PFAS. Computers and smartphones still need PFAS,” Loeffler said. “Cutting them out completely is not realistic, but we can certainly eliminate their nonessential uses and try to figure out how to accelerate their full degradation.”

Partial degradation is not sufficient; many polyfluorinated molecules break down into the more recalcitrant, complicated, and dangerous perfluorinated substances. Loeffler and other scientists are still trying to find out what biotic and abiotic processes facilitate the processes that lead to complete PFAS detoxification.

“The idea would be to find naturally occurring processes that degrade these chemicals over time,” he said. “We could then potentially manipulate environments to encourage those processes and remediate at least some sites that are heavily contaminated with PFAS.”

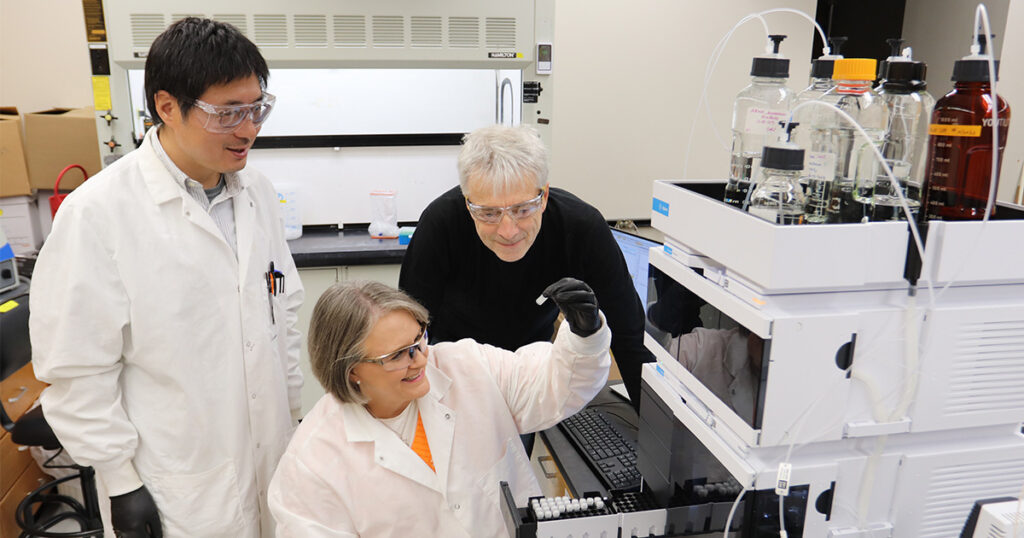

PFAS analysis is not trivial. The instruments that can identify and quantify the different molecules—liquid chromatography/triple quadrupole mass spectrometers (LC/TQs)—are expensive instruments that can only be operated by specially trained technicians.

“Typical wait times for commercial instruments can run up to 10 weeks,” said Swift, “and analyzing a single sample can cost up to $1,000. One experiment may require running dozens of samples, so the cost becomes tremendous.”

Fortunately, with funding from the UT Office of Research, Innovation, and Economic Development, the Loeffler lab was recently able to purchase its very own LC/TQ system and have Swift trained as an expert in its operation.

“In addition to reaching the lower limits of PFAS detection that the Environmental Protection Agency is now pushing for, this instrument decreases our cost of analysis to about $50 per sample,” Swift said. “Once it’s up and running, I will be able to load over 100 samples at a time, each of which can be processed in about 20 minutes.”

Access to highly accurate PFAS analytic capability is often a prerequisite for successful PFAS research proposals. Having an in-house LC/TQ gives UT researchers access to a broad range of federally funded PFAS studies and remediation programs.

“Our new instrument creates enormous opportunities for PFAS researchers across campus,” Loeffler said. “The PFAS problem is a global crisis. Tackling it will require the work of experts across many disciplines for years to come.”

Researchers from across UT can reach out to Cindy Swift to learn more about the PFAS analytical capabilities of the new LC/TQ and to reserve space on it for suitable experiments.

“Whether you’re studying groundwater, sewage, landfill waste, municipal water, or the Tennessee River, we can help,” she said.

Contact

Izzie Gall (865-974-7203, egall4@utk.edu)