Rock Salt Gives Clues to Improve Energy Sector

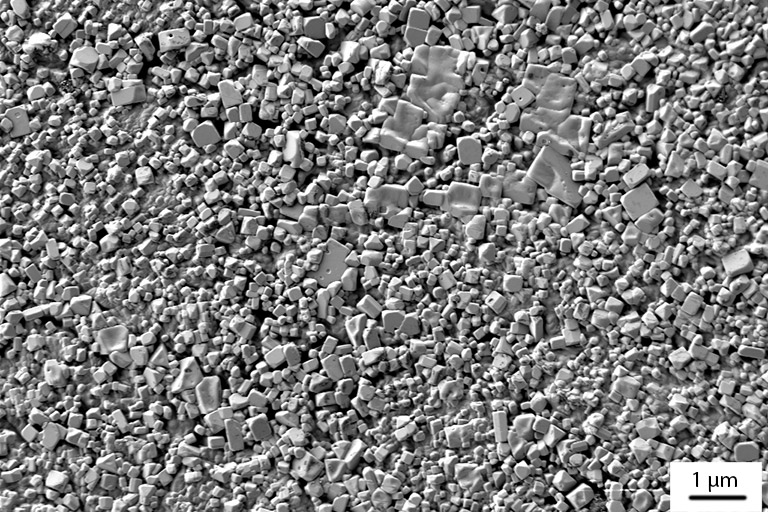

A rock salt sample made of millions of small rock salt crystals under SEM microscope.

Rock salt is probably best known for its use in thawing icy roads or in making homemade ice cream, but it also plays a key role in energy safety and security.

A CEE research team working under Professor Khalid Alshibli is studying the salt, also known as halite, at the microscopic level to better understand how best to manage it at much bigger sizes. Specifically, undergraduate student Darcie Halliburton and graduate student Amirsalar Moslehy are hoping to improve the stability of underground salt caverns used to store nuclear waste.

Left to right: Darcie Haliburton and Amirsalar Moslehy

Halliburton looks at samples of thousands of grains in one-millimeter by two-millimeter cylinders using in-situ 3D synchrotron micro-computed tomography and 3D X-ray diffraction methods at Argonne National Laboratory. With crystallographic scans of the samples, she can then study the orientations of individual grains to identify how they are impacting the whole sample.

Individual grains of a material may not seem like they would matter in the bigger scheme of things, but, taken as a whole, the mechanical behavior of the grains can help engineers crack the code on creating even greater designs.

“We can see what would happen if the grains are aligned horizontally or their corners are up or randomly directed,” said Halliburton. “With this study, engineers can go into greater depth to understand the stability of the structure.”

More unknowns mean more factors of safety that civil engineers have to take into account. Likewise, with more knowledge at the foundational level, engineers can predict the behavior more accurately. Applied to a structure, it might mean that if the material is unknown it must be considered weak, and then a building can’t safely be assumed to have as many floors, but with more information, engineers could potentially build more floors.

Moslehy is working to unlock the micro-scale mysteries that could help the energy sector more safely build artificially constructed underground rock salt caverns. These caverns, located up to one kilometer below the earth’s surface, have been used in the energy industry for 50 years in storing fossil fuels, natural gas, nuclear waste, compressed gas used in renewable energy like hydrogen, and are the subject of ongoing geotechnical research.

“One of the first steps to constructing a salt cavern is to drill a well hole that can sometimes be a kilometer deep into the earth,” said Moslehy. “This research can help determine if the rock salt cavern is going to be safe over its lifespan.”

Moslehy drills holes and grooves into a small two-inch long sample and cuts them with different orientations. He then pulls them apart and observes the forces and deformations that have occurred inside the sample using images from a high-speed digital camera.

These images show micrometer-scale deformations occurring every few microseconds, which can let Moslehy know how the drilled crack has propagated deformations inside the sample. The end result of these experiments can identify how much force is needed to fracture the rock salt crystal in different orientations or angles.

Nuclear waste stored in caverns is at elevated temperatures at the time of disposal, or it may generate heat with time, while some of the stored gases are cooled at the time of injection into the cavern. Moreover, some of these caverns have naturally hot temperatures, so Moslehy is conducting more experiments at a wide range of temperatures and under different loading conditions to investigate the rock salt’s mechanical behavior.