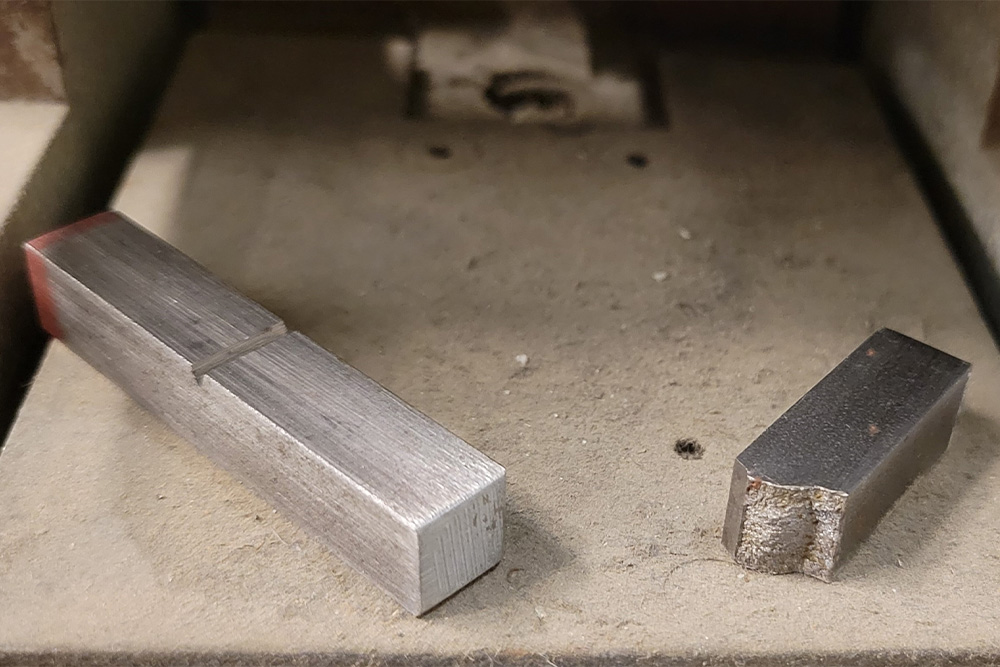

With familiar apprehension, Sarah Mobley released the lever and watched the 50-pound hammer head swing downward. At the bottom of its arc, it snapped a metal sample in half, then swung up to eye level again on the other side of the support pillar. As the metal fragments impacted the padding across from her, Mobley pressed the brake button, slowly bringing the pendulum to stop.

“It’s a little Draconian, isn’t it?” she said.

Mobley is a teaching associate professor in the Department of Civil and Environmental Engineering (CEE). She joined the University of Tennessee faculty in 2019, 56 years after the hammer made its debut on Rocky Top.

“This impact tester is a very well-built piece of equipment. It still works fine,” Mobley said. “But it’s no longer produced or serviced.”

Impact testers are meant to report how much force is needed to break a sample, which allows civil engineers to estimate the strength of a material. Mobley uses this one to show students how the strength of a metal changes with mineral composition and temperature.

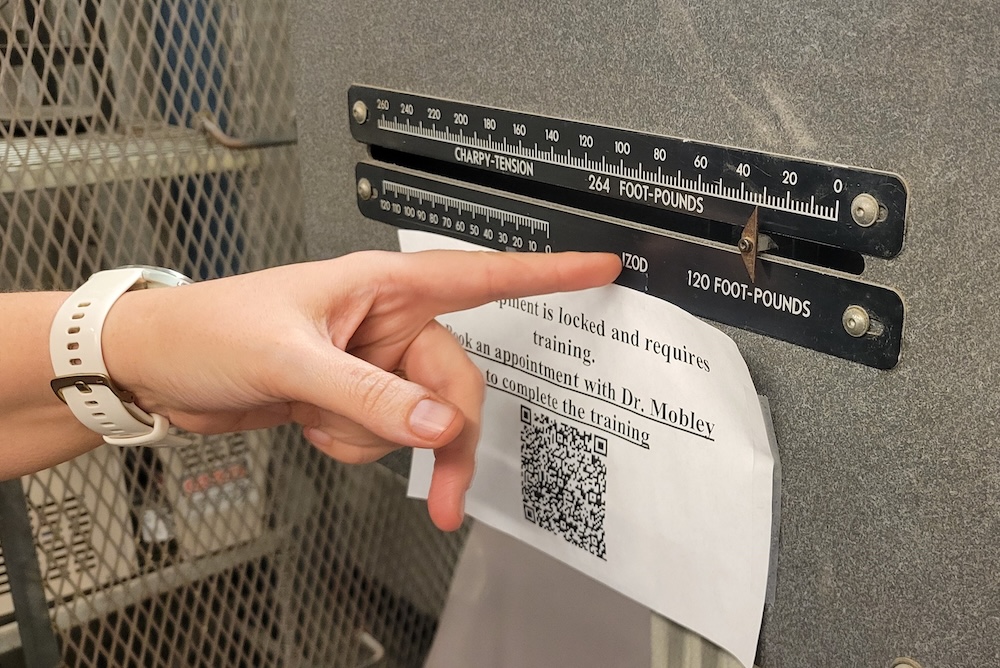

Unfortunately, since the machine can no longer be calibrated, its readings are entirely relative. Mobley can demonstrate which of two metal samples is stronger, but more precise readings—such as those needed for research—are impossible.

That means the large machine can only be used for a single lab course, serving a maximum of 60 undergraduates for one week per year. Most of the time, it gathers dust behind a whiteboard.

But for Mobley, who chairs the University of Tennessee Laboratory Safety Committee, the machine’s main drawback is the threat to student safety.

“We’ve never had a safety issue with it,” she said as she closed the padlock that keeps the hammer in its down position when it’s not in use. “But it’s terrifying to have a bunch of students around it.”

Last year, when an anonymous donor offered to upgrade equipment within the Tickle College of Engineering, Mobley submitted a proposal for multiple pieces of equipment, including a new Instron drop tower. As a result of her case statement and advocacy, the new Instron machine will arrive at the Ed Burdette Hardened Concrete Laboratory this April, upgrading the undergraduate curriculum and bringing new research capabilities to the department.

“We can do all sorts of different impact tests with this that we couldn’t do with the hammer,” Mobley said, “and it increases the safety of the lab dramatically.”

Engineering a Safety-First Environment

Mobley strongly believes in hands-on education and in making safety a central part of every learning experience.

“If we are working safely, we’re doing a lot of things correctly,” she said. “When students know that they’re in an environment that will keep them safe, that empowers them to run the equipment and do the procedures themselves—and anytime they can do something instead of watching something be done, they get a deeper level of understanding.”

Mobley teaches her students that clear communication and respect do not only contribute to a truly safe space; they also help engineers remember that their colleagues are people, rather than assets that help complete a procedure. When built into the curriculum, safety can become a self-sustaining methodology.

The fact that Mobley’s proposal was chosen demonstrates that this philosophy extends into the industry.

“The new impact tester was the only upgrade that was approved (from Mobley’s larger proposal), and that is because it has a direct impact on the safety of our undergraduate population,” she said. “These donors are very interested in keeping safety first and foremost, and I think that should be a model for everyone going through engineering.”

Local Donors Enrich Education, Research, Workforce

When the new impact tester arrives, its first function will be enriching Mobley’s undergraduate lab course. The drop tower-based machine will allow student groups to conduct their own experiments, data collection, and troubleshooting.

As Mobley explores the expanded features of the new machine, she hopes to incorporate it in other labs throughout the semester. Several research professors in CEE and the Department of Materials Science and Engineering have also begun making plans with Mobley to use the new equipment in their research.

While the new equipment will immediately benefit students and researchers at UT, Mobley also emphasized the impact it will have on the local workforce.

Since many UT engineering graduates stay in the Knoxville area, local donors like CEE’s anonymous benefactor can directly influence the level of experience their future employees have.

“Learning how to use a piece of equipment that’s this new and this state-of-the-art gives them additional value in the workplace that knowing how to use an outdated and obsolete piece of equipment doesn’t,” she said. “When this kind of upgrade comes from local companies and alumni donors, we’re reinforcing the network that they were already a part of. I love that.”

Contact

Izzie Gall (865-974-7203, egall4@utk.edu)